Decoding Zara: Understanding Its Supply Chain And Design Process

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Decoding Zara: Understanding its Supply Chain and Design Process

Zara, the Spanish fast-fashion giant, has revolutionized the retail industry with its incredibly fast turnaround time from design to store shelves. But how does it do it? This article delves into the intricacies of Zara's remarkably efficient supply chain and innovative design process, revealing the secrets behind its phenomenal success.

Zara's Lightning-Fast Supply Chain: A Case Study in Efficiency

Zara's competitive advantage lies not just in its trendy designs, but in its meticulously optimized supply chain. Unlike many competitors who rely heavily on long-term contracts and large-scale production, Zara embraces a highly responsive, flexible model. Key elements include:

-

Vertical Integration: Zara owns a significant portion of its production process, giving it greater control over quality, lead times, and costs. This vertical integration extends from design and manufacturing to distribution and retail.

-

Proximity Manufacturing: A large percentage of Zara's garments are produced in factories located relatively close to its headquarters in Galicia, Spain. This significantly reduces transportation time and allows for quicker adjustments to trends and demand.

-

Just-in-Time Production: Instead of producing massive quantities in advance, Zara produces smaller batches of clothing based on real-time sales data. This minimizes the risk of unsold inventory and allows for rapid adaptation to changing consumer preferences.

-

Agile Technology: Zara utilizes advanced technology, including sophisticated software and data analytics, to track sales, manage inventory, and forecast demand with remarkable accuracy. This data-driven approach informs production decisions and ensures that the right products are in the right place at the right time.

-

Small Batch Production & Frequent Releases: Instead of large seasonal collections, Zara releases new designs frequently, often weekly. This constant stream of new arrivals keeps customers engaged and coming back for more.

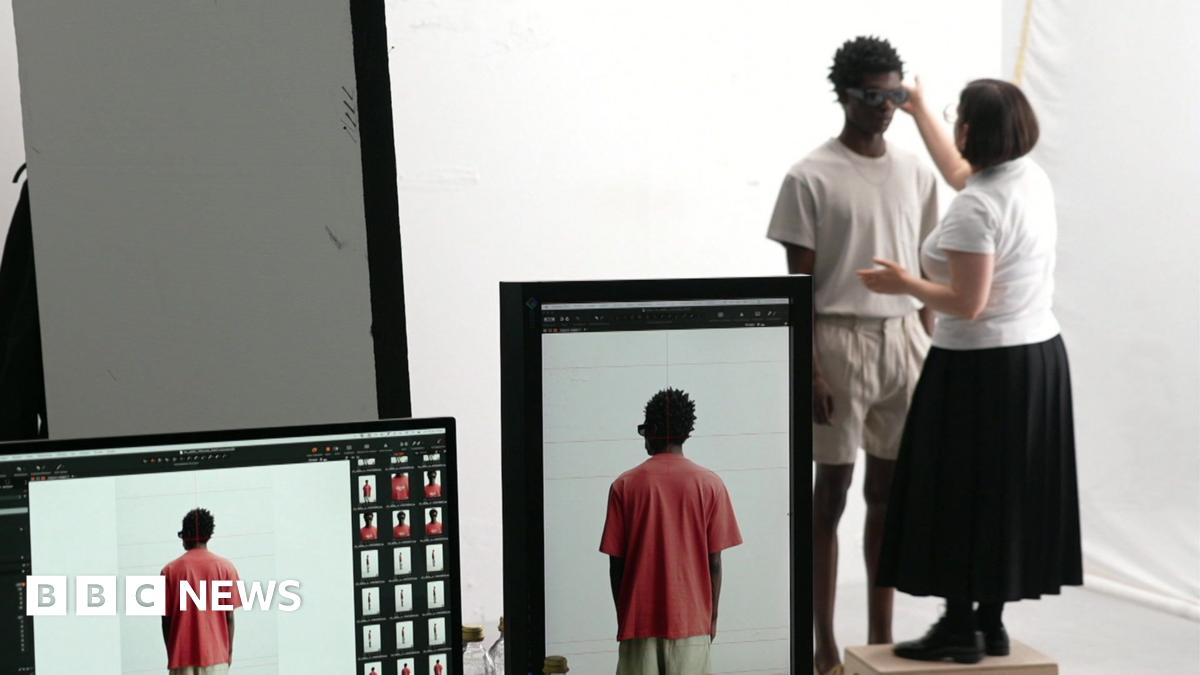

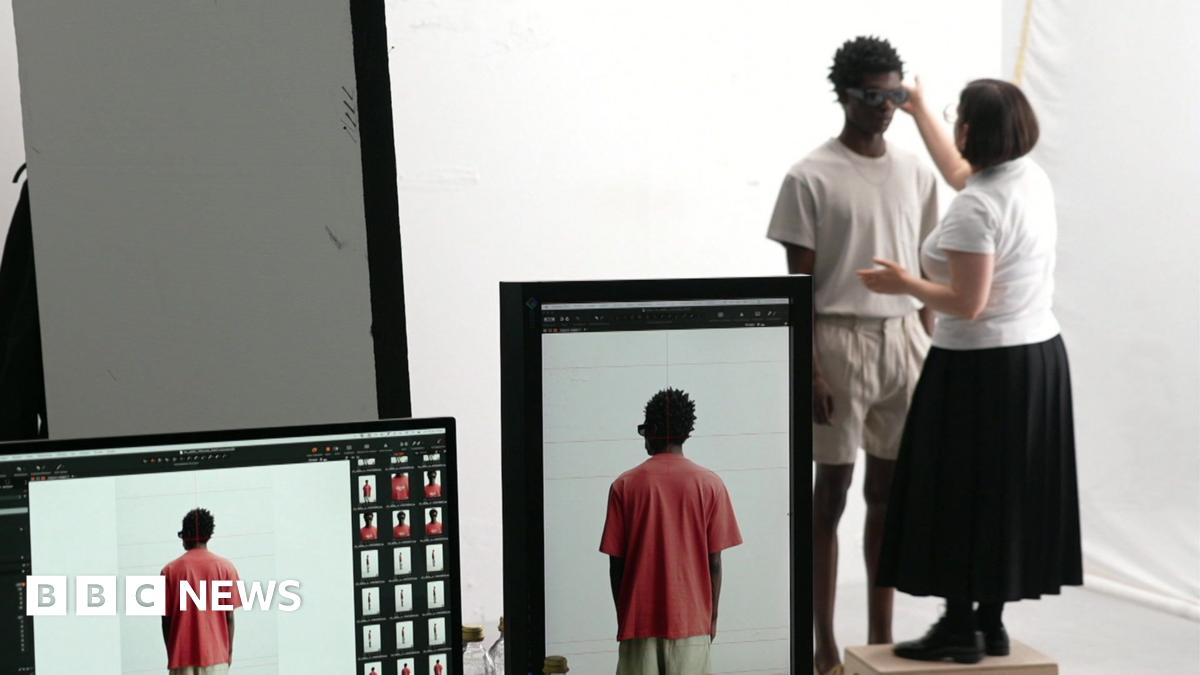

The Zara Design Process: From Trendspotting to Store Shelves

Zara's design process is as crucial as its supply chain. It's a fast-paced, collaborative effort focused on translating current trends into marketable garments quickly.

-

Trend Scouting: Zara employs a dedicated team of trend scouts who constantly monitor global fashion trends, social media, and street style to identify potential designs.

-

Rapid Prototyping and Production: Once a design is finalized, prototypes are quickly produced and tested. This iterative process ensures that designs are both fashionable and practical.

-

Short Design Cycles: Zara's design cycles are significantly shorter than those of its competitors, allowing it to react quickly to changing trends and consumer demand.

-

Data-Driven Design: Sales data plays a crucial role in Zara's design process. Trends that prove popular are quickly scaled up, while less successful designs are swiftly discontinued.

Challenges and Criticisms

While Zara's model is undeniably successful, it also faces criticisms. Concerns around ethical labor practices and sustainability have been raised, prompting calls for greater transparency and accountability within its supply chain.

The Future of Zara's Model

Zara's continued success will depend on its ability to adapt to evolving consumer preferences, technological advancements, and increasing scrutiny regarding its sustainability practices. While the company has made some strides in addressing these concerns, ongoing efforts are necessary to ensure its long-term viability.

In conclusion, Zara's success is a testament to its mastery of both design and supply chain management. By combining vertical integration, proximity manufacturing, just-in-time production, and sophisticated data analytics, Zara has created a highly responsive and efficient system that allows it to dominate the fast-fashion market. However, addressing ethical and sustainability concerns remains a critical challenge for the company's future.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Decoding Zara: Understanding Its Supply Chain And Design Process. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Archibald Prize Winner 2024 Celebrating Julie Fragars Triumph

May 09, 2025

Archibald Prize Winner 2024 Celebrating Julie Fragars Triumph

May 09, 2025 -

World Surf Tour Coasters Dominate Home Event

May 09, 2025

World Surf Tour Coasters Dominate Home Event

May 09, 2025 -

May 6 2025 Golden State Warriors Minnesota Timberwolves Game Report

May 09, 2025

May 6 2025 Golden State Warriors Minnesota Timberwolves Game Report

May 09, 2025 -

Pak Minister Humiliated On Live Uk Tv Terror Link Grilling

May 09, 2025

Pak Minister Humiliated On Live Uk Tv Terror Link Grilling

May 09, 2025 -

I Let It Happen Jay Leno Takes Responsibility For Kimmel Interview

May 09, 2025

I Let It Happen Jay Leno Takes Responsibility For Kimmel Interview

May 09, 2025