Intel's 18 Angstrom Chips On Track For Second Half Of 2025 Mass Production

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Intel's 18 Angstrom Chips: Mass Production on Track for Late 2025

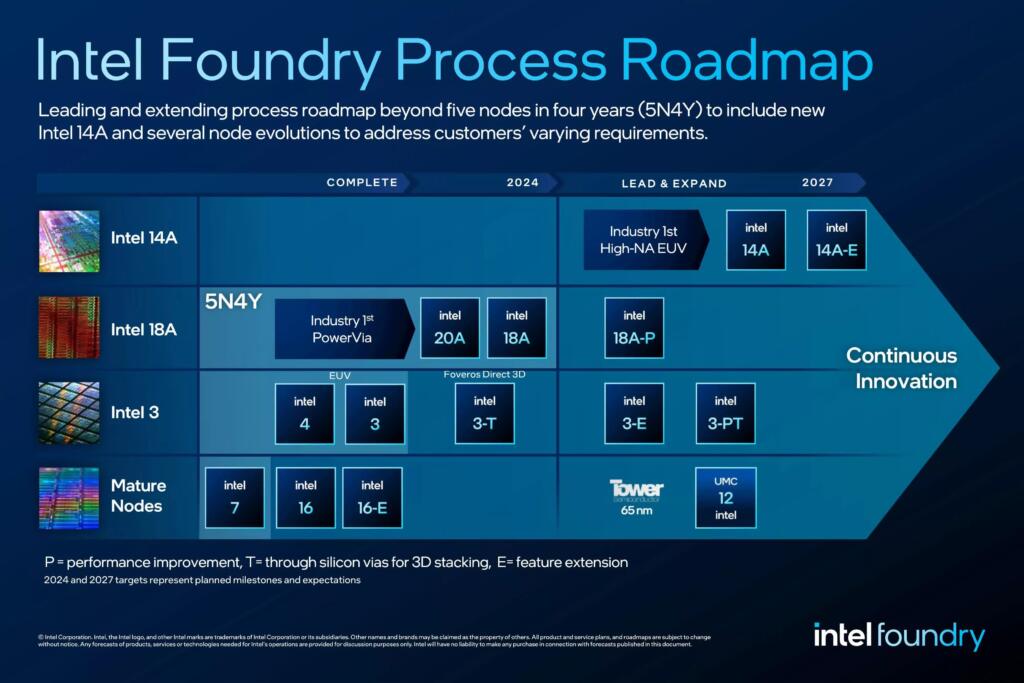

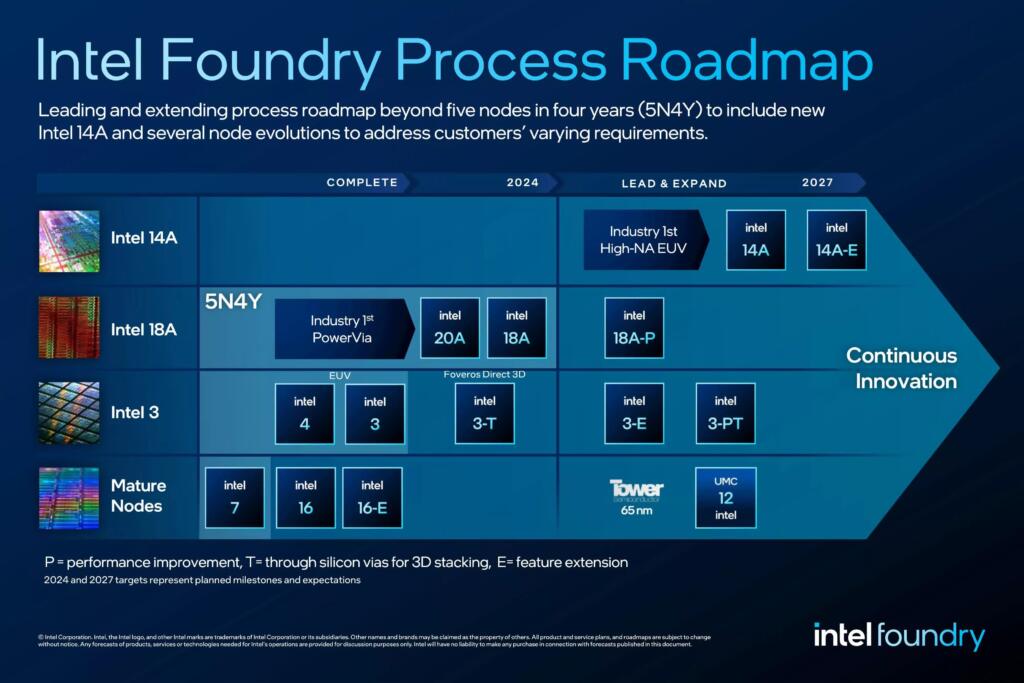

Intel is forging ahead with its ambitious 18 Angstrom chip development, aiming for mass production in the second half of 2025. This groundbreaking technology promises a significant leap forward in computing power and efficiency, potentially reshaping the landscape of the semiconductor industry. The announcement confirms Intel's continued commitment to leading-edge process technology and solidifies its position in the competitive chip market.

Intel's 18 Angstrom process, a significant advancement over its current 7nm and upcoming 3nm nodes, will utilize a new architecture designed for enhanced performance and power efficiency. This represents a crucial step in Intel's bid to regain its manufacturing leadership and compete effectively against industry giants like TSMC and Samsung.

<h3>What Makes 18 Angstrom Technology So Significant?</h3>

The move to 18 Angstrom represents a substantial reduction in transistor size, leading to several key advantages:

- Increased Performance: Smaller transistors allow for higher clock speeds and improved computational capabilities, resulting in faster processing speeds for various applications.

- Reduced Power Consumption: Smaller transistors consume less power, leading to increased battery life in mobile devices and lower energy costs in data centers.

- Higher Transistor Density: More transistors can be packed onto a single chip, boosting performance and enabling more complex functionalities.

- Improved Cost Efficiency: While initial investments are substantial, the increased density and efficiency could ultimately lead to lower production costs per chip in the long run.

These improvements are crucial for powering next-generation technologies, including artificial intelligence, high-performance computing, and advanced mobile devices.

<h3>Challenges and Future Implications</h3>

While Intel's roadmap is ambitious, the transition to 18 Angstrom technology isn't without its challenges. Developing and manufacturing chips at such a small scale requires overcoming significant technical hurdles related to lithography, materials science, and yield optimization.

However, the potential rewards are substantial. Successful mass production of 18 Angstrom chips could significantly boost Intel's market share and solidify its position as a leading semiconductor manufacturer. This advancement will have a ripple effect across various industries, driving innovation in areas like:

- Data Centers: Enhanced performance and energy efficiency are critical for large-scale data centers, enabling faster processing and reduced operational costs.

- Artificial Intelligence: AI applications demand immense computational power; 18 Angstrom chips could accelerate AI development and deployment.

- High-Performance Computing (HPC): Scientific research and simulations require powerful processors; this technology will enable breakthroughs in fields like medicine, climate modeling, and materials science.

- Mobile Devices: Improved power efficiency translates to longer battery life and enhanced performance in smartphones, tablets, and other mobile devices.

<h3>Intel's Strategy and Competition</h3>

Intel's aggressive investment in 18 Angstrom technology is a clear indication of its strategy to regain its manufacturing leadership. This move positions Intel to compete directly with TSMC and Samsung, who are also aggressively pursuing advanced node technologies. The success of Intel's 18 Angstrom chips will be a significant factor in determining the future landscape of the semiconductor industry. The race to smaller, faster, and more energy-efficient chips is on, and Intel's commitment to its 2025 production goal signals a confident entry into this critical next phase. The coming years will be crucial in observing the real-world impact and market adoption of this innovative technology.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Intel's 18 Angstrom Chips On Track For Second Half Of 2025 Mass Production. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Llama 4 Vs Chat Gpt And Gemini Metas Ai Faces Tough Competition

Apr 08, 2025

Llama 4 Vs Chat Gpt And Gemini Metas Ai Faces Tough Competition

Apr 08, 2025 -

Uk Faces 111bn Budget Gap After Non Dom Tax Crackdown

Apr 08, 2025

Uk Faces 111bn Budget Gap After Non Dom Tax Crackdown

Apr 08, 2025 -

Space X Super Heavy Booster 14 Relaunch Date For Starship Flight 9

Apr 08, 2025

Space X Super Heavy Booster 14 Relaunch Date For Starship Flight 9

Apr 08, 2025 -

Buffett Vende Acciones De Apple Caida Del 13 En Su Participacion

Apr 08, 2025

Buffett Vende Acciones De Apple Caida Del 13 En Su Participacion

Apr 08, 2025 -

Investimentos Da Berkshire Apos A Saida De Buffett Greg Abel Toma As Redeas

Apr 08, 2025

Investimentos Da Berkshire Apos A Saida De Buffett Greg Abel Toma As Redeas

Apr 08, 2025