Overcoming Battery Constraints: Tesla's Approach To Supply Chain Management

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

<h1>Overcoming Battery Constraints: Tesla's Approach to Supply Chain Management</h1>

Tesla's meteoric rise in the electric vehicle (EV) market hinges on a crucial component: the battery. Securing a reliable and scalable supply of high-quality batteries has been, and continues to be, a significant challenge for the entire EV industry. However, Tesla has distinguished itself through a proactive and innovative approach to supply chain management, demonstrating a commitment to vertical integration and strategic partnerships that are reshaping the landscape of battery production.

<h2>Navigating the Complexities of Battery Supply Chains</h2>

The production of EV batteries is a complex process, requiring a diverse range of raw materials, including lithium, cobalt, nickel, and manganese, sourced from geographically dispersed locations. Geopolitical instability, fluctuating commodity prices, and environmental concerns all contribute to the inherent volatility of the battery supply chain. Traditional automotive manufacturers often relied on established supplier networks, leaving them vulnerable to disruptions. Tesla, however, has adopted a different strategy.

<h3>Vertical Integration: From Raw Materials to Finished Product</h3>

Tesla's strategy isn't simply about securing battery cells; it's about controlling as much of the production process as possible. This vertical integration strategy minimizes reliance on external suppliers, mitigating risks associated with shortages and price hikes. By investing in mining operations, refining facilities, and battery cell manufacturing plants, Tesla aims to secure its supply of crucial materials and reduce its dependence on the whims of the global market. This strategic move allows for greater control over quality, cost, and timelines, a critical factor in maintaining production targets.

<h3>Strategic Partnerships: Collaboration for Success</h3>

While vertical integration is a cornerstone of Tesla's approach, the company also recognizes the value of strategic partnerships. Collaborations with companies specializing in specific aspects of battery production allow Tesla to leverage expertise and resources, complementing its internal capabilities. These partnerships offer access to cutting-edge technologies and innovative production techniques, fostering continuous improvement and innovation within the battery supply chain. Examples include collaborations with Panasonic, LG Energy Solution, and CATL, showcasing Tesla’s ability to forge strong relationships with leading battery technology providers.

<h2>Innovation and Sustainability: Key Pillars of Tesla's Battery Strategy</h2>

Beyond securing supply, Tesla's battery strategy focuses heavily on innovation and sustainability. The company is actively researching and developing next-generation battery technologies, including advancements in battery chemistry, cell design, and manufacturing processes. This commitment to innovation ensures Tesla stays at the forefront of battery technology, improving energy density, charging speeds, and overall performance, while simultaneously reducing costs. Furthermore, Tesla prioritizes sustainable sourcing of raw materials and environmentally responsible manufacturing practices, addressing growing concerns about the environmental impact of battery production.

<h3>Key Takeaways: Tesla's Winning Formula</h3>

- Vertical Integration: Controlling key aspects of the production process, from raw materials to finished batteries.

- Strategic Partnerships: Leveraging external expertise and resources for a more robust and flexible supply chain.

- Innovation: Continuously developing and implementing next-generation battery technologies.

- Sustainability: Prioritizing environmentally responsible sourcing and manufacturing.

Tesla’s approach to battery supply chain management represents a paradigm shift in the automotive industry. By embracing vertical integration, strategic partnerships, and a commitment to innovation and sustainability, Tesla has not only secured its own battery supply but has also set a new standard for the entire EV sector, paving the way for a more resilient and sustainable future for electric vehicles. The company’s proactive and multifaceted strategy serves as a valuable case study for other manufacturers striving to overcome the challenges of battery production and secure their place in the rapidly evolving EV market.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Overcoming Battery Constraints: Tesla's Approach To Supply Chain Management. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

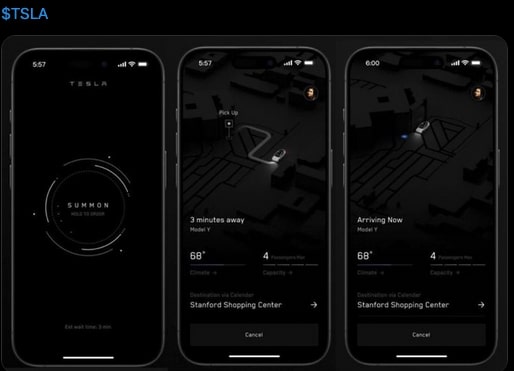

Tesla Ridesharing Austin Pilot Program With Supervised And Unsupervised Models Expected In June

May 15, 2025

Tesla Ridesharing Austin Pilot Program With Supervised And Unsupervised Models Expected In June

May 15, 2025 -

Impact Of Reduced Tariffs On Cheap Chinese Goods Under Trump

May 15, 2025

Impact Of Reduced Tariffs On Cheap Chinese Goods Under Trump

May 15, 2025 -

A Ghostly Revelation Aunt Lydias Spiritual Journey In The Handmaids Tale

May 15, 2025

A Ghostly Revelation Aunt Lydias Spiritual Journey In The Handmaids Tale

May 15, 2025 -

Super Micros Stock Weighing The Potential Downsides And Rewards

May 15, 2025

Super Micros Stock Weighing The Potential Downsides And Rewards

May 15, 2025 -

Singapores Fair Price Launches 2025 Return Voucher Program

May 15, 2025

Singapores Fair Price Launches 2025 Return Voucher Program

May 15, 2025

Latest Posts

-

Conquer The Nyt Mini Crossword May 13 2025 Tips And Tricks

May 15, 2025

Conquer The Nyt Mini Crossword May 13 2025 Tips And Tricks

May 15, 2025 -

Nintendo Switch 2 New Battery Management To Maximize Lifespan

May 15, 2025

Nintendo Switch 2 New Battery Management To Maximize Lifespan

May 15, 2025 -

Teslas Innovative Solutions To Secure Battery Supply For Electric Vehicles

May 15, 2025

Teslas Innovative Solutions To Secure Battery Supply For Electric Vehicles

May 15, 2025 -

Microsoft Announces 6 000 Layoffs A 3 Workforce Reduction

May 15, 2025

Microsoft Announces 6 000 Layoffs A 3 Workforce Reduction

May 15, 2025 -

Did Twilio Experience A Data Breach Company Addresses Steam 2 Fa Concerns

May 15, 2025

Did Twilio Experience A Data Breach Company Addresses Steam 2 Fa Concerns

May 15, 2025