Tesla Austin: The Rise Of Unmanned Vehicle Production

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Tesla Austin: The Rise of Unmanned Vehicle Production

Tesla's Gigafactory in Austin, Texas, is rapidly becoming more than just a car manufacturing plant; it's a pioneering hub for the future of automotive production, increasingly reliant on unmanned systems and automation. This ambitious undertaking marks a significant leap forward in Tesla's quest for efficiency, scalability, and ultimately, lower vehicle prices. But the road to fully unmanned vehicle production is paved with challenges. Let's delve into the current state and future prospects of this revolutionary approach.

Automation at the Heart of Gigafactory Texas

The Gigafactory in Austin isn't just automating individual tasks; it's aiming for a holistic, interconnected system. From the initial stages of raw material handling to the final vehicle assembly, robots and AI-powered systems are playing a crucial role. This includes:

- Automated Guided Vehicles (AGVs): These unmanned robots transport materials and components across the factory floor, optimizing logistics and minimizing human intervention. Their precise movements and efficient routing contribute significantly to streamlined production.

- Robotic Assembly Lines: Robots handle tasks ranging from welding and painting to intricate parts installation, performing repetitive actions with speed and accuracy exceeding human capabilities. This reduces human error and improves overall quality control.

- AI-powered Quality Control: Advanced vision systems and machine learning algorithms monitor the production process, detecting defects and anomalies in real-time. This proactive approach ensures high-quality standards are consistently maintained.

- Predictive Maintenance: Data analytics and AI algorithms predict potential equipment failures, allowing for preventative maintenance and minimizing downtime. This contributes to enhanced efficiency and reduced production delays.

The Challenges of Unmanned Vehicle Production

While the benefits of automation are clear, transitioning to a fully unmanned factory presents significant hurdles:

- Initial Investment Costs: Implementing advanced robotics and AI systems requires a substantial upfront investment. This can be a barrier to entry for smaller manufacturers.

- Software and Integration Complexity: Creating a seamlessly integrated system of robots, AI, and human-machine interfaces requires sophisticated software and expertise. System failures can have cascading effects on production.

- Cybersecurity Risks: A highly automated factory is vulnerable to cyberattacks, which could disrupt operations and potentially compromise sensitive data. Robust cybersecurity measures are paramount.

- Job Displacement Concerns: The increasing automation of manufacturing processes naturally raises concerns about job displacement. Tesla and other manufacturers are addressing this by focusing on retraining and upskilling programs for their workforce.

The Future of Unmanned Vehicle Production at Tesla Austin

Tesla's commitment to unmanned vehicle production at its Austin Gigafactory signifies a broader trend in the automotive industry. The pursuit of greater efficiency, scalability, and cost reduction is driving the adoption of advanced automation technologies. While challenges remain, the potential benefits – including increased production capacity, improved quality, and potentially lower vehicle prices – are significant. The continued development and refinement of AI and robotics will play a crucial role in shaping the future of automotive manufacturing, with Tesla's Austin Gigafactory at the forefront of this revolution. We can expect to see further advancements in unmanned systems in the coming years, solidifying Tesla’s position as a leader in this exciting and transformative field.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Tesla Austin: The Rise Of Unmanned Vehicle Production. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Penjelasan Lengkap Video Viral Gunung Gede Meletus 2 April 2025

Apr 11, 2025

Penjelasan Lengkap Video Viral Gunung Gede Meletus 2 April 2025

Apr 11, 2025 -

Tottenham Vs Eintracht Frankfurt Quarter Final Clash Live Score And Updates

Apr 11, 2025

Tottenham Vs Eintracht Frankfurt Quarter Final Clash Live Score And Updates

Apr 11, 2025 -

Todays Stock Market Analysis Of Dow S And P 500 And Nasdaq Performance In Light Of Geopolitical Events

Apr 11, 2025

Todays Stock Market Analysis Of Dow S And P 500 And Nasdaq Performance In Light Of Geopolitical Events

Apr 11, 2025 -

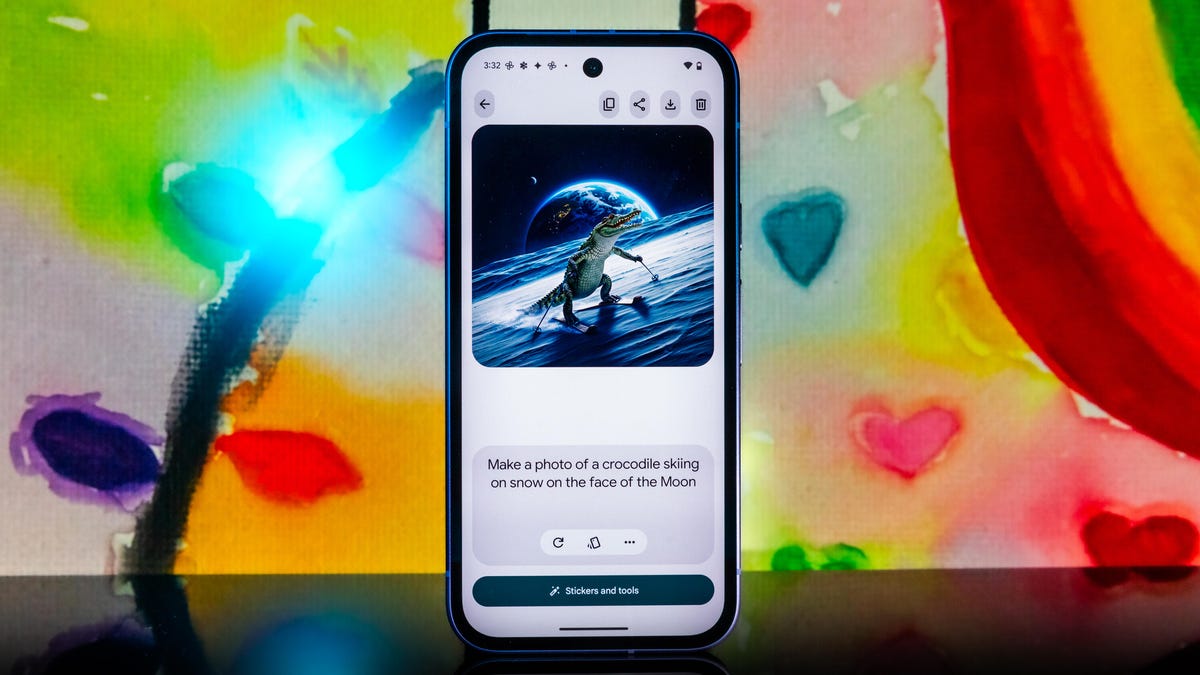

Google Pixel 9a A Budget Friendly Smartphone Review

Apr 11, 2025

Google Pixel 9a A Budget Friendly Smartphone Review

Apr 11, 2025 -

Tyrrell Hatton Interview Overcoming Masters Difficulties

Apr 11, 2025

Tyrrell Hatton Interview Overcoming Masters Difficulties

Apr 11, 2025