$25K Tesla By 2025? Inside Tesla's Factory Transformation.

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

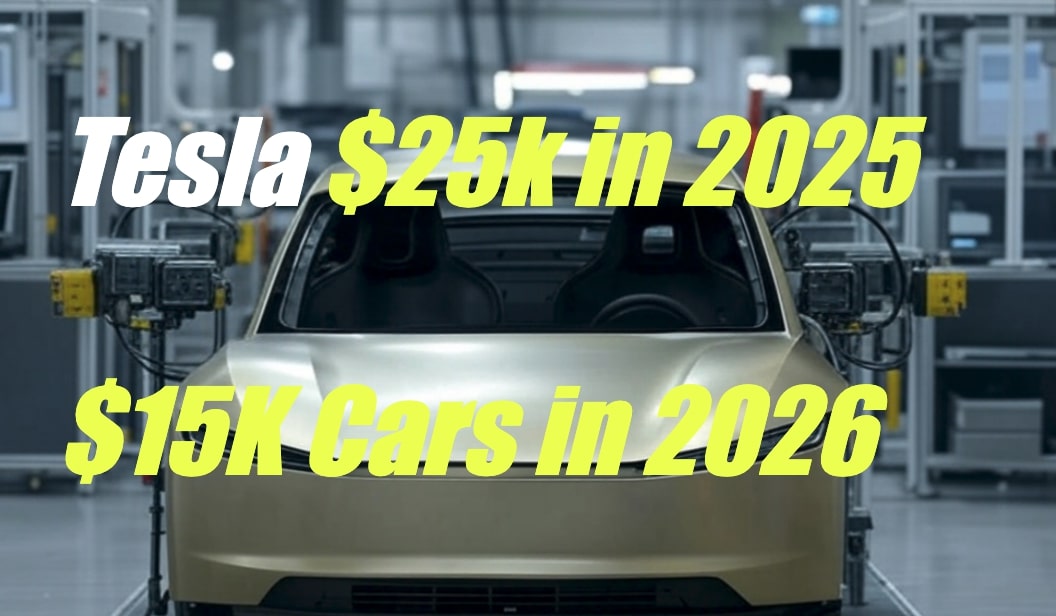

$25K Tesla by 2025? Inside Tesla's Factory Transformation

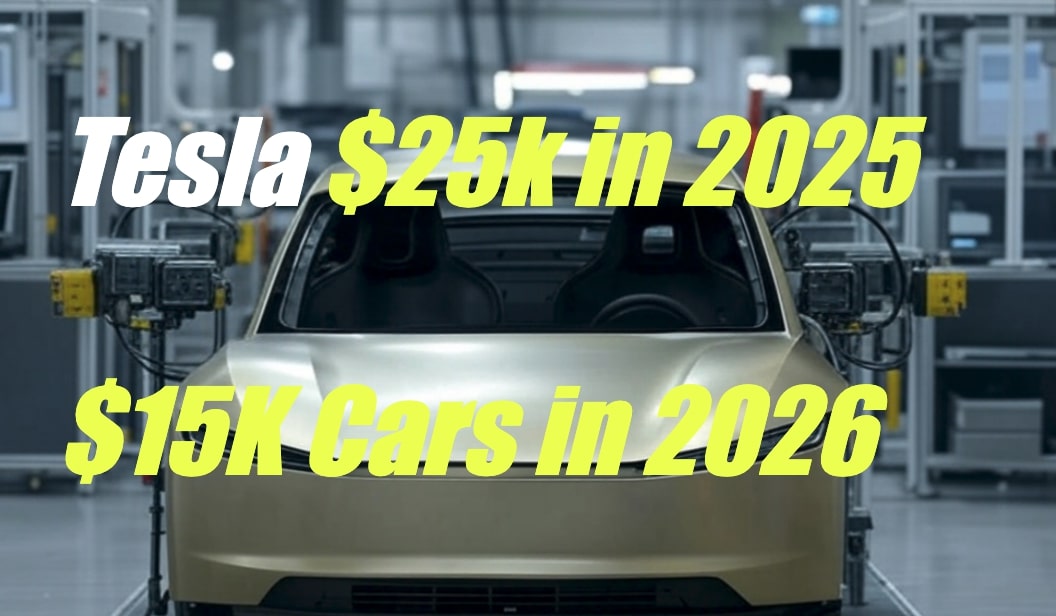

Tesla's ambitious goal of producing a $25,000 electric vehicle (EV) by 2025 has sent ripples through the automotive industry. This isn't just a price point; it represents a potential paradigm shift, making EVs accessible to a significantly wider market. But how will Elon Musk & Co. achieve this seemingly impossible feat? The answer lies within Tesla's ongoing factory transformation, a complex and ambitious undertaking involving automation, streamlined production, and a focus on cost reduction across the board.

The Quest for Affordability: More Than Just a Lower Price Tag

A $25,000 Tesla isn't simply about slashing the price of existing models. It signifies a fundamental restructuring of Tesla's manufacturing processes. This affordability target necessitates a complete overhaul, impacting everything from raw material sourcing and supply chain management to the assembly line itself. The implications are far-reaching, potentially reshaping the entire EV landscape.

Key Pillars of Tesla's Factory Transformation:

-

Increased Automation: Tesla is heavily investing in robotics and automation to increase efficiency and reduce labor costs. This includes advanced manufacturing techniques like AI-powered quality control and predictive maintenance, minimizing downtime and optimizing resource allocation.

-

Next-Generation Battery Technology: Battery production costs account for a significant portion of an EV's overall price. Tesla is actively pursuing advancements in battery technology, exploring cheaper materials and more efficient manufacturing processes to drastically lower battery costs. This includes their own in-house battery production and the development of 4680 battery cells.

-

Streamlined Supply Chain: Optimizing the supply chain is crucial. This involves securing reliable sources for raw materials, improving logistics, and minimizing transportation costs. Vertical integration, where Tesla controls more stages of the production process, plays a key role in this strategy.

-

Design Simplification: While maintaining Tesla's signature design aesthetics, the company is likely exploring ways to simplify the design of the $25,000 model. This could mean fewer features or a more streamlined manufacturing process for individual components.

-

Gigafactory Expansion and Optimization: Tesla's Gigafactories are central to this plan. The company is continuously expanding its manufacturing capacity and optimizing existing facilities for maximum efficiency. Innovations in production layout and process flow are vital for hitting the ambitious cost targets.

Challenges and Uncertainties:

While the vision is compelling, challenges remain. Maintaining quality while drastically reducing costs is a delicate balancing act. Competition from other EV manufacturers is fierce, and securing the necessary raw materials and skilled labor in sufficient quantities presents a significant hurdle. Furthermore, unexpected economic factors could impact the timeline and feasibility of the project.

The Impact on the EV Market:

A successful $25,000 Tesla would be a game-changer. It could accelerate the global transition to electric vehicles, making them accessible to a vastly larger consumer base and potentially displacing internal combustion engine vehicles much faster than currently projected. This would have significant implications for the environment and the global automotive industry as a whole.

Conclusion:

Tesla's pursuit of a $25,000 EV by 2025 is a bold and ambitious undertaking. The success hinges on the effectiveness of their factory transformation, a multifaceted strategy requiring innovation across various areas. While significant challenges remain, the potential impact on the EV market and the broader automotive industry is undeniable, making this a story worth closely following.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on $25K Tesla By 2025? Inside Tesla's Factory Transformation.. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Is Amazon Amzn A Top Investment Think Investments Perspective

Apr 07, 2025

Is Amazon Amzn A Top Investment Think Investments Perspective

Apr 07, 2025 -

Dow Futures Continue Freefall Amidst Broader Market Sell Off

Apr 07, 2025

Dow Futures Continue Freefall Amidst Broader Market Sell Off

Apr 07, 2025 -

Mobile Legends Pembagian Grup Resmi Turnamen Esl Sps Mobile Masters 2025

Apr 07, 2025

Mobile Legends Pembagian Grup Resmi Turnamen Esl Sps Mobile Masters 2025

Apr 07, 2025 -

Solana Sol Price Alert Key Support Level Under Threat Of Breakdown

Apr 07, 2025

Solana Sol Price Alert Key Support Level Under Threat Of Breakdown

Apr 07, 2025 -

Space X And The Pentagon Testing Sub Orbital Hour Long Military Flights Starting 2026

Apr 07, 2025

Space X And The Pentagon Testing Sub Orbital Hour Long Military Flights Starting 2026

Apr 07, 2025