Navigating The Battery Crisis: Tesla's Approach To Supply Chain Management

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Navigating the Battery Crisis: Tesla's Approach to Supply Chain Management

The global automotive industry faces a significant hurdle: securing a reliable supply of batteries to fuel the electric vehicle (EV) revolution. This "battery crisis" threatens to slow down the transition to sustainable transportation, but companies like Tesla are proactively addressing the challenge with innovative supply chain strategies. Tesla's approach, characterized by vertical integration, strategic partnerships, and a relentless focus on efficiency, offers valuable lessons for navigating this crucial industry bottleneck.

Tesla's Vertical Integration Strategy: A Key Differentiator

Unlike many automakers who rely heavily on external battery suppliers, Tesla has aggressively pursued vertical integration. This means controlling various stages of the battery production process, from raw material sourcing to cell manufacturing and pack assembly. This strategy offers several key advantages:

- Secured Supply: By owning key parts of the supply chain, Tesla reduces its vulnerability to disruptions caused by supplier shortages or price fluctuations. This is especially crucial for critical battery materials like lithium, cobalt, and nickel.

- Quality Control: Vertical integration allows Tesla to maintain tighter control over the quality of its batteries, ensuring consistent performance and longevity. This is paramount for customer satisfaction and brand reputation.

- Innovation Acceleration: Owning the entire process facilitates faster innovation. Tesla can rapidly test and implement new battery technologies without the delays and complexities associated with coordinating with multiple external suppliers.

Strategic Partnerships: Expanding the Reach and Expertise

While vertical integration is a cornerstone of Tesla's strategy, they also leverage strategic partnerships to supplement their capabilities. Collaborations with mining companies secure access to raw materials, while partnerships with technology providers contribute to advancements in battery chemistry and manufacturing processes. This balanced approach combines the benefits of control with access to specialized expertise and resources.

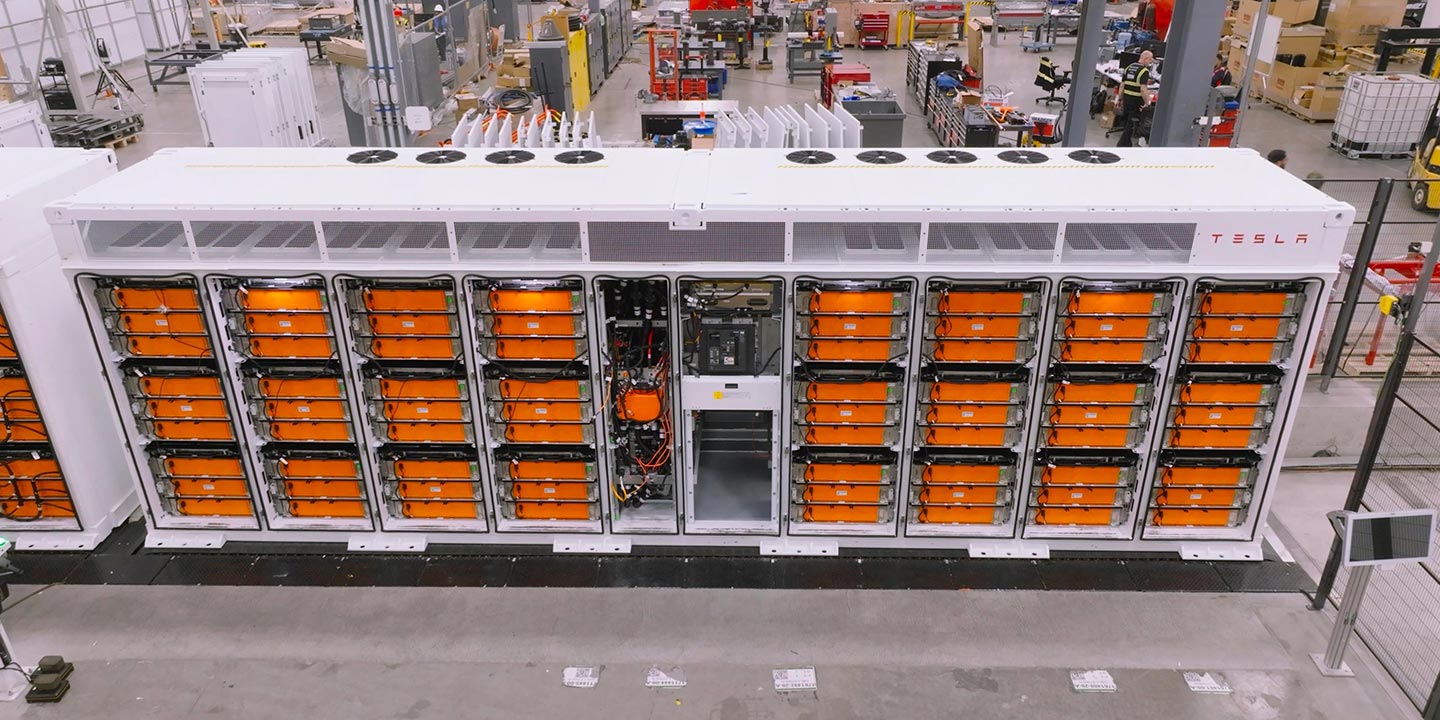

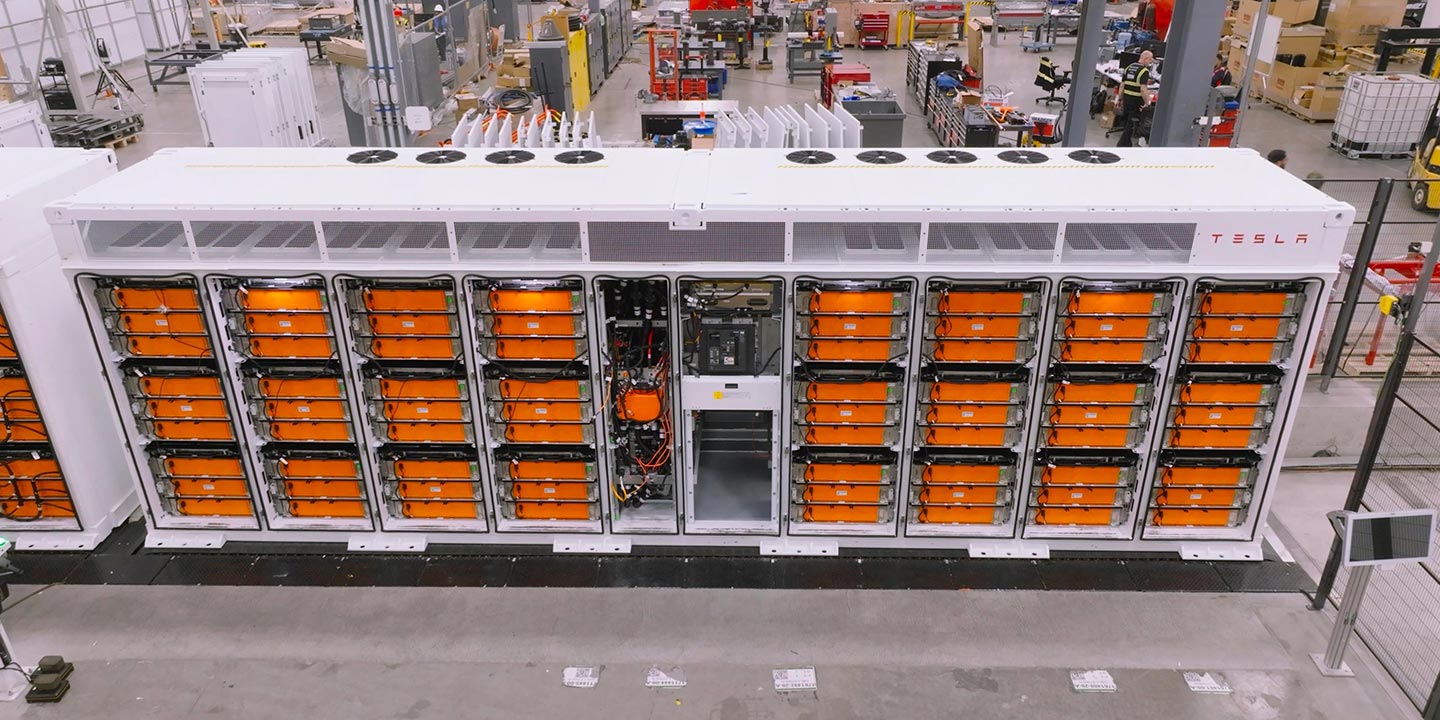

Gigafactories: A Symbol of Tesla's Ambitious Scale

Tesla's network of Gigafactories represents a significant investment in battery production capacity. These massive facilities are strategically located across the globe to minimize transportation costs and optimize proximity to key markets. The sheer scale of these factories allows Tesla to produce batteries at a volume necessary to meet its ambitious production targets and contribute to the overall growth of the EV market.

Sustainability and Ethical Sourcing: Beyond Profitability

Tesla's commitment to sustainability is integrated into its supply chain strategy. The company actively works to source materials responsibly, prioritizing ethical mining practices and minimizing environmental impact. This commitment is not only crucial for maintaining a positive brand image but also secures access to resources in a world increasingly focused on environmental, social, and governance (ESG) factors.

Challenges and Future Outlook

Despite its advancements, Tesla faces ongoing challenges. The demand for battery materials continues to surge, creating intense competition and potential price volatility. Scaling up production while maintaining quality and sustainability standards is also a continuous effort. However, Tesla's proactive and integrated approach positions the company favorably to navigate these challenges and maintain its leadership in the EV market. The company’s innovative solutions and strategic foresight serve as a blueprint for other automakers striving to overcome the battery crisis and accelerate the global transition to electric mobility.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Navigating The Battery Crisis: Tesla's Approach To Supply Chain Management. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Geopolitical Tensions Shift Pakistan Super League To The Uae

May 10, 2025

Geopolitical Tensions Shift Pakistan Super League To The Uae

May 10, 2025 -

Brooklyn Beckham And Nicola Peltz Family Tensions And A Missed Birthday

May 10, 2025

Brooklyn Beckham And Nicola Peltz Family Tensions And A Missed Birthday

May 10, 2025 -

Round Nine Preview Team News Stats And Expert Predictions

May 10, 2025

Round Nine Preview Team News Stats And Expert Predictions

May 10, 2025 -

Controversy Erupts Kanye Wests New Song Removed From Streaming

May 10, 2025

Controversy Erupts Kanye Wests New Song Removed From Streaming

May 10, 2025 -

Christian Pulisic Shines As Ac Milan Defeat Bologna In Coppa Italia Prep

May 10, 2025

Christian Pulisic Shines As Ac Milan Defeat Bologna In Coppa Italia Prep

May 10, 2025

Latest Posts

-

Nuggets Vs Thunder Russell Westbrooks Game 3 Availability Questioned

May 10, 2025

Nuggets Vs Thunder Russell Westbrooks Game 3 Availability Questioned

May 10, 2025 -

The Hidden Danger One Third Of It Workers Employing Unauthorized Ai

May 10, 2025

The Hidden Danger One Third Of It Workers Employing Unauthorized Ai

May 10, 2025 -

The Future Of Global Ai Data Centers Analyzing Amazon And Microsofts Influence

May 10, 2025

The Future Of Global Ai Data Centers Analyzing Amazon And Microsofts Influence

May 10, 2025 -

Strives Public Debut Reshaping Corporate Bitcoin Adoption And Key Performance Indicators

May 10, 2025

Strives Public Debut Reshaping Corporate Bitcoin Adoption And Key Performance Indicators

May 10, 2025 -

New Isa Rules Understanding Penalties For Early Access

May 10, 2025

New Isa Rules Understanding Penalties For Early Access

May 10, 2025