Right To Repair: How The US Army's Policy Change Impacts Equipment Lifecycle Management

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Right to Repair: How the US Army's Policy Change Impacts Equipment Lifecycle Management

The US Army's recent shift towards a more open "Right to Repair" policy is sending ripples through the defense industry and significantly impacting how the military manages the lifecycle of its equipment. This groundbreaking change, long advocated for by independent repair shops and consumer advocates, promises greater efficiency, cost savings, and enhanced operational readiness. But what exactly does this mean, and what are the potential ramifications?

What is the Army's New Right to Repair Policy?

For years, the military relied heavily on Original Equipment Manufacturers (OEMs) for repairs and maintenance of its complex equipment. This often resulted in lengthy repair times, high costs, and reliance on a single vendor. The Army's updated policy aims to break this dependency by granting greater access to repair information, parts, and diagnostic tools to authorized third-party repair facilities. This means independent repair shops, potentially even within the Army itself, can now service a wider range of military equipment.

Key Impacts on Equipment Lifecycle Management:

This policy shift has profound implications across the entire lifecycle of military equipment:

- Reduced Downtime: Faster repairs translate directly into reduced downtime for critical equipment, improving operational readiness and mission success rates. This is particularly crucial in rapidly evolving operational environments.

- Significant Cost Savings: By opening the market to competition, the Army can expect to negotiate lower repair costs. The elimination of sole-source dependency reduces the leverage OEMs previously held.

- Enhanced Supply Chain Resilience: Diversifying the repair network strengthens the supply chain, making it less vulnerable to disruptions from single points of failure. This is critical in addressing current supply chain challenges facing the Department of Defense.

- Increased Innovation: The increased accessibility to equipment data may spur innovation in repair techniques and technologies, leading to better and more cost-effective solutions. Independent repair shops may develop unique solutions not considered by OEMs.

- Improved Sustainability: The ability to repair equipment extends its lifespan, reducing waste and promoting a more sustainable approach to military logistics. This aligns with growing concerns about environmental responsibility within the Department of Defense.

Challenges and Considerations:

While the benefits are considerable, the implementation of this policy presents some challenges:

- Data Security: Protecting sensitive military data within the expanded repair ecosystem requires robust security protocols and oversight. This will be a key focus area in the policy's implementation.

- Maintaining Quality Standards: Ensuring that third-party repairs meet the rigorous quality standards required for military equipment is crucial for maintaining operational safety and reliability. Strict certifications and oversight will be needed.

- Training and Certification: Training and certifying personnel from third-party repair shops to work on complex military equipment will be a significant undertaking. Investing in robust training programs is paramount.

The Future of Military Equipment Maintenance:

The Army's embrace of the Right to Repair is a significant step towards a more flexible, efficient, and cost-effective approach to equipment lifecycle management. While challenges remain, the potential benefits – improved operational readiness, substantial cost savings, and enhanced supply chain resilience – make this a crucial policy shift with far-reaching implications for the future of military operations. The success of this initiative will depend on careful implementation, robust oversight, and a collaborative approach between the Army, OEMs, and independent repair providers. The long-term impact on military readiness and budget efficiency remains to be seen, but the potential for positive change is undeniable.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on Right To Repair: How The US Army's Policy Change Impacts Equipment Lifecycle Management. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Sensationelle Saisonenden Bvb Und Eintracht Frankfurt Spielen Champions League Heidenheim Muss In Die Relegation

May 18, 2025

Sensationelle Saisonenden Bvb Und Eintracht Frankfurt Spielen Champions League Heidenheim Muss In Die Relegation

May 18, 2025 -

Jonquel Jones Net Worth 2023 Liberty Stars Salary And Career Earnings

May 18, 2025

Jonquel Jones Net Worth 2023 Liberty Stars Salary And Career Earnings

May 18, 2025 -

Amds Next Radeon Gpu Computex 2025 Launch Hints At Nvidia Competition

May 18, 2025

Amds Next Radeon Gpu Computex 2025 Launch Hints At Nvidia Competition

May 18, 2025 -

Thunder Vs Nuggets Nba Analyzes Russell Westbrooks Impact

May 18, 2025

Thunder Vs Nuggets Nba Analyzes Russell Westbrooks Impact

May 18, 2025 -

How To Watch The Las Vegas Aces Vs New York Liberty Game Live

May 18, 2025

How To Watch The Las Vegas Aces Vs New York Liberty Game Live

May 18, 2025

Latest Posts

-

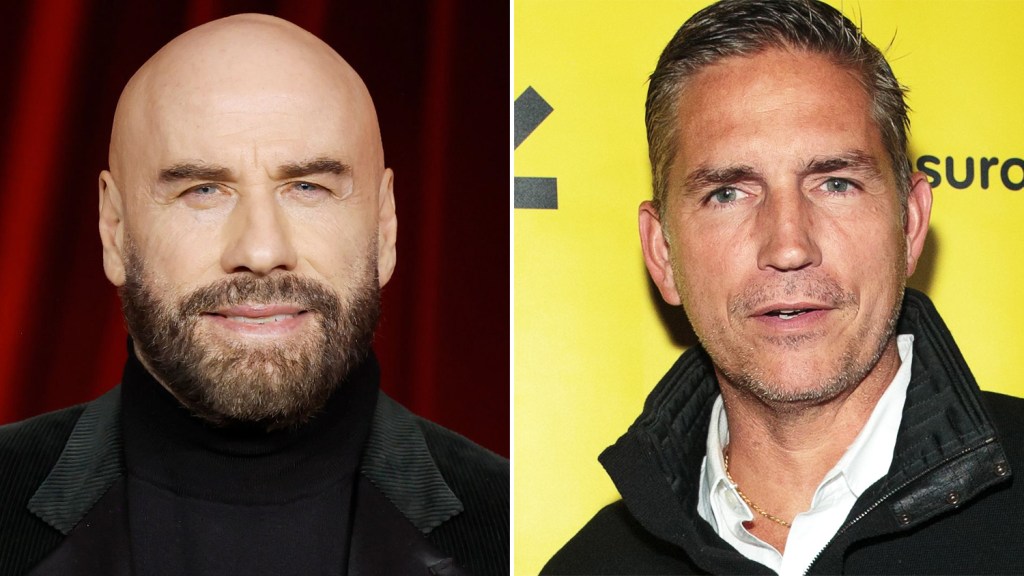

Jim Caviezel And John Travolta Team Up For Faith Based Action Film Syndicate

May 18, 2025

Jim Caviezel And John Travolta Team Up For Faith Based Action Film Syndicate

May 18, 2025 -

Warren Buffetts Investing Principles And Their Application To Cryptocurrency

May 18, 2025

Warren Buffetts Investing Principles And Their Application To Cryptocurrency

May 18, 2025 -

100 Million Inflows Fail To Push Pi Network Pi Above 1 A Market Deep Dive

May 18, 2025

100 Million Inflows Fail To Push Pi Network Pi Above 1 A Market Deep Dive

May 18, 2025 -

Primera Derrota Del Barca En El Camp Nou Analisis Del Partido

May 18, 2025

Primera Derrota Del Barca En El Camp Nou Analisis Del Partido

May 18, 2025 -

Luke Bryan Farm Tour 2024 Erik Nelsons Role Revealed

May 18, 2025

Luke Bryan Farm Tour 2024 Erik Nelsons Role Revealed

May 18, 2025