The Technological Leap In Tesla Cybercab Production: A SpaceX Starship Analogy

Welcome to your ultimate source for breaking news, trending updates, and in-depth stories from around the world. Whether it's politics, technology, entertainment, sports, or lifestyle, we bring you real-time updates that keep you informed and ahead of the curve.

Our team works tirelessly to ensure you never miss a moment. From the latest developments in global events to the most talked-about topics on social media, our news platform is designed to deliver accurate and timely information, all in one place.

Stay in the know and join thousands of readers who trust us for reliable, up-to-date content. Explore our expertly curated articles and dive deeper into the stories that matter to you. Visit NewsOneSMADCSTDO now and be part of the conversation. Don't miss out on the headlines that shape our world!

Table of Contents

Tesla Cybercab Production: A Giant Leap for Electric Vehicles – Mirroring SpaceX's Starship Ambitions

Tesla's highly anticipated Cybercab, the electric pickup truck designed to redefine the automotive landscape, is facing a production challenge on a scale comparable to SpaceX's Starship development. The sheer ambition of the project, packed with cutting-edge technology and innovative manufacturing techniques, presents a fascinating parallel to SpaceX's ambitious interplanetary transportation goals. This article delves into the technological leaps required for Cybercab production and explores the similarities with SpaceX's Starship program.

H2: The Cybercab's Technological Marvels:

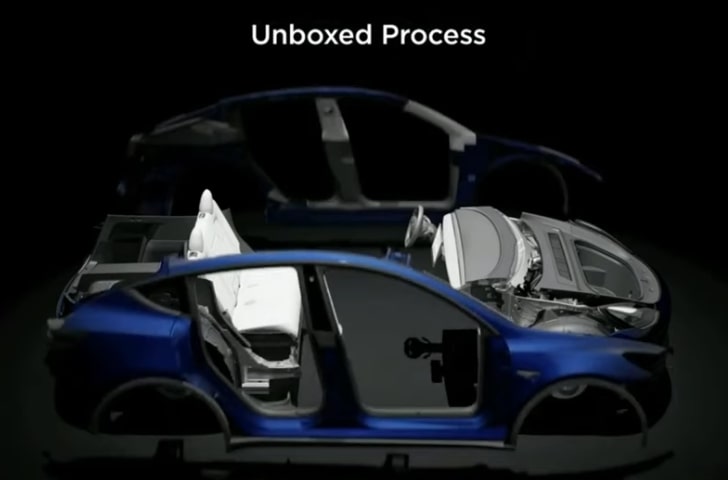

The Tesla Cybercab isn't just another electric pickup truck; it's a rolling testament to technological innovation. Its exoskeleton design, using ultra-hardened stainless steel, demands entirely new manufacturing processes. This isn't simply stamping out sheet metal; it's forging a robust, durable chassis capable of withstanding extreme conditions. This innovative approach echoes SpaceX's Starship development, which utilizes advanced materials and manufacturing techniques to build a spacecraft capable of withstanding the rigors of space travel.

- Exoskeleton Construction: The Cybercab's unique exoskeleton requires specialized robotic welding and precision manufacturing, demanding a level of automation and technological sophistication similar to the complexities of Starship construction.

- Battery Technology: Tesla's advancements in battery technology are critical to the Cybercab's success. Higher energy density, faster charging times, and improved range are all crucial elements, reflecting the demanding energy requirements of SpaceX's Starship for long-duration space missions.

- Software and Autonomous Driving: The Cybercab is expected to feature Tesla's advanced Autopilot and Full Self-Driving capabilities. This intricate software integration mirrors the complexity of Starship's autonomous flight control systems, requiring rigorous testing and development.

H2: Production Challenges: A Starship-Scale Undertaking:

Producing the Cybercab at scale presents significant logistical and engineering hurdles. The unique exoskeleton construction necessitates the development of entirely new manufacturing processes and robotic systems. This mirrors the challenges faced by SpaceX in developing the Starship's manufacturing infrastructure, requiring massive investments in specialized facilities and technology.

- Gigafactory Expansion: Tesla's Gigafactories will need significant upgrades and expansions to accommodate Cybercab production. This scaling-up mirrors SpaceX's development of its Starship production facilities in Boca Chica, Texas.

- Supply Chain Management: Securing a reliable supply chain for the specialized materials and components required for Cybercab production is a massive undertaking, similar to the complex supply chains required for Starship's multitude of parts.

- Quality Control: Maintaining consistent quality across a high-volume production line for such a technologically advanced vehicle demands stringent quality control measures, reflecting the critical need for perfect execution in Starship's assembly process.

H3: Lessons Learned from SpaceX:

SpaceX's iterative development process, characterized by rapid prototyping, testing, and continuous improvement, provides valuable lessons for Tesla's Cybercab production. The willingness to embrace failure as a learning opportunity and adapt quickly to challenges is crucial for both projects. Both companies demonstrate a relentless pursuit of innovation and a commitment to pushing the boundaries of what's technologically possible.

H2: Conclusion: The Future of Electric Vehicles and Space Exploration Converge:

The Tesla Cybercab's production journey represents a significant technological leap, mirroring the ambitious goals of SpaceX's Starship program. The challenges faced in producing this innovative electric vehicle highlight the parallels between advancements in automotive technology and space exploration. The success of both ventures will redefine their respective industries and shape the future of transportation, both on Earth and beyond. The coming years will be crucial in witnessing the realization of these ambitious projects and their impact on the world.

Thank you for visiting our website, your trusted source for the latest updates and in-depth coverage on The Technological Leap In Tesla Cybercab Production: A SpaceX Starship Analogy. We're committed to keeping you informed with timely and accurate information to meet your curiosity and needs.

If you have any questions, suggestions, or feedback, we'd love to hear from you. Your insights are valuable to us and help us improve to serve you better. Feel free to reach out through our contact page.

Don't forget to bookmark our website and check back regularly for the latest headlines and trending topics. See you next time, and thank you for being part of our growing community!

Featured Posts

-

Ex Nrl Star Wiliame Takes The Reins Of Bulldogs Womens Rugby League Team

Apr 07, 2025

Ex Nrl Star Wiliame Takes The Reins Of Bulldogs Womens Rugby League Team

Apr 07, 2025 -

Gold Market Analysis Bulls And Bears Clash On Future Price Direction

Apr 07, 2025

Gold Market Analysis Bulls And Bears Clash On Future Price Direction

Apr 07, 2025 -

A History Of Martian Maps The Rivalries That Shaped Our Perception Of The Red Planet

Apr 07, 2025

A History Of Martian Maps The Rivalries That Shaped Our Perception Of The Red Planet

Apr 07, 2025 -

Tariffs And Market Fears Buffetts Poem For Investors

Apr 07, 2025

Tariffs And Market Fears Buffetts Poem For Investors

Apr 07, 2025 -

2025 March Madness Finals The Ultimate Viewing Guide

Apr 07, 2025

2025 March Madness Finals The Ultimate Viewing Guide

Apr 07, 2025